Light vehicles

Light duty vehicles

Heavy trucks

Public works

Agricultural vehicles

Lifting equipment

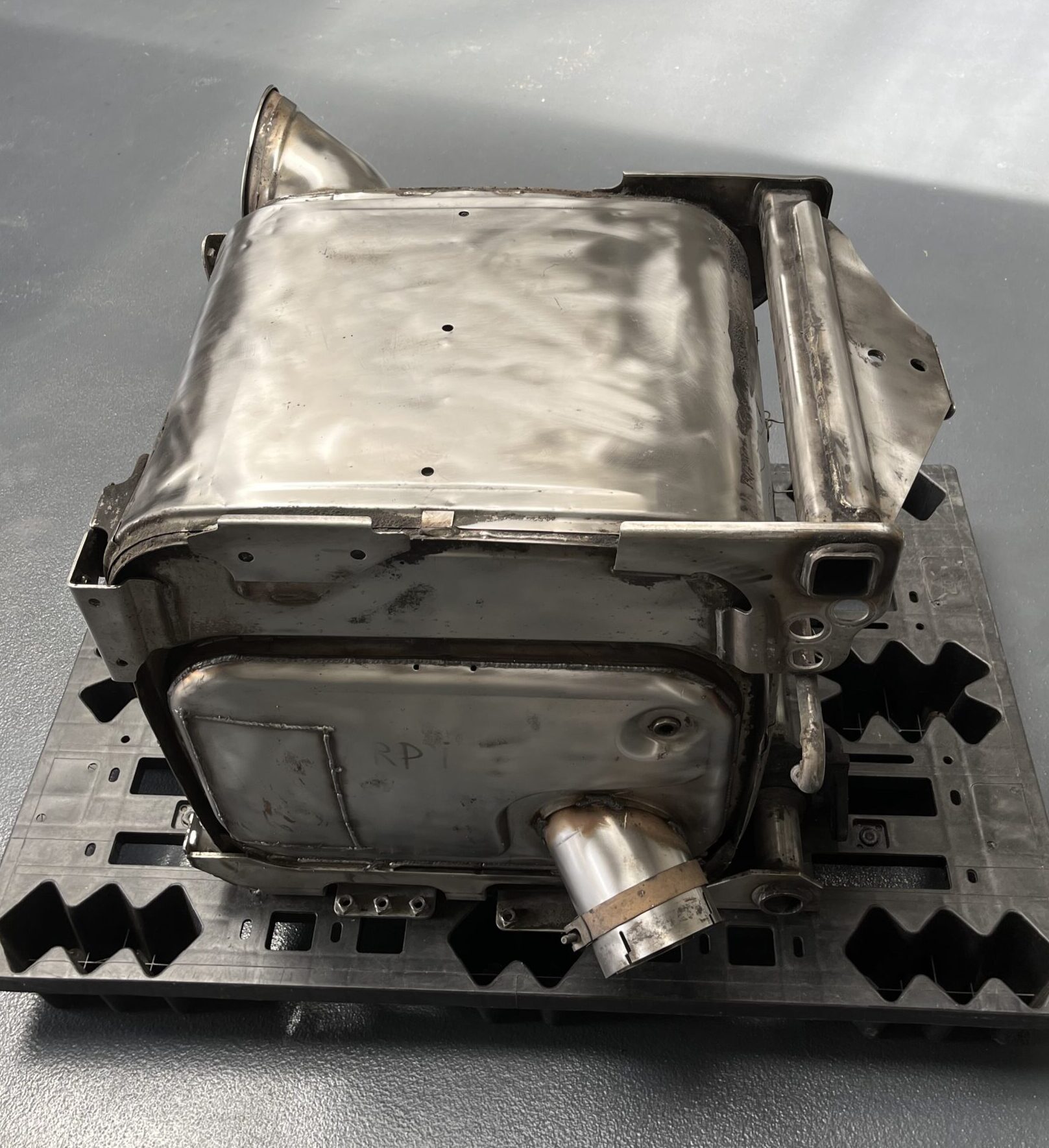

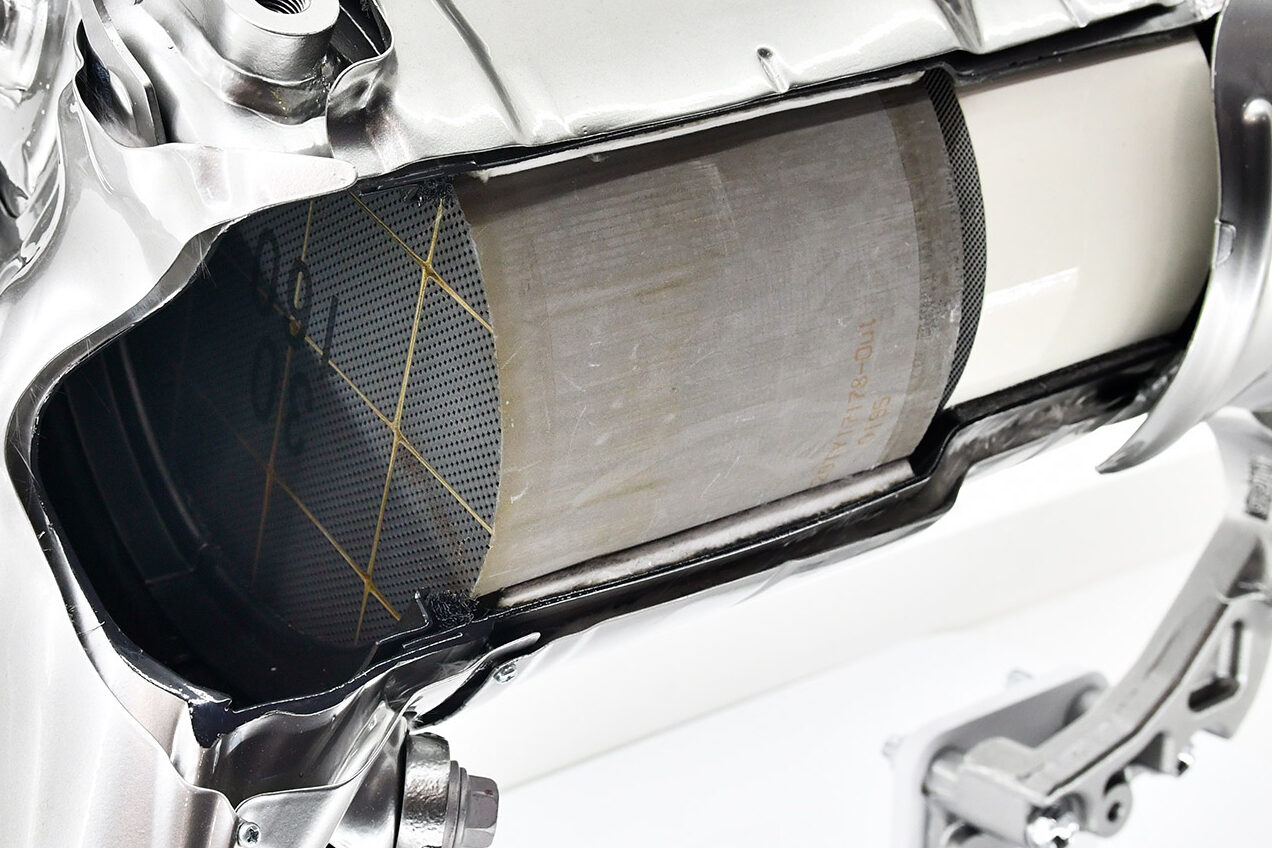

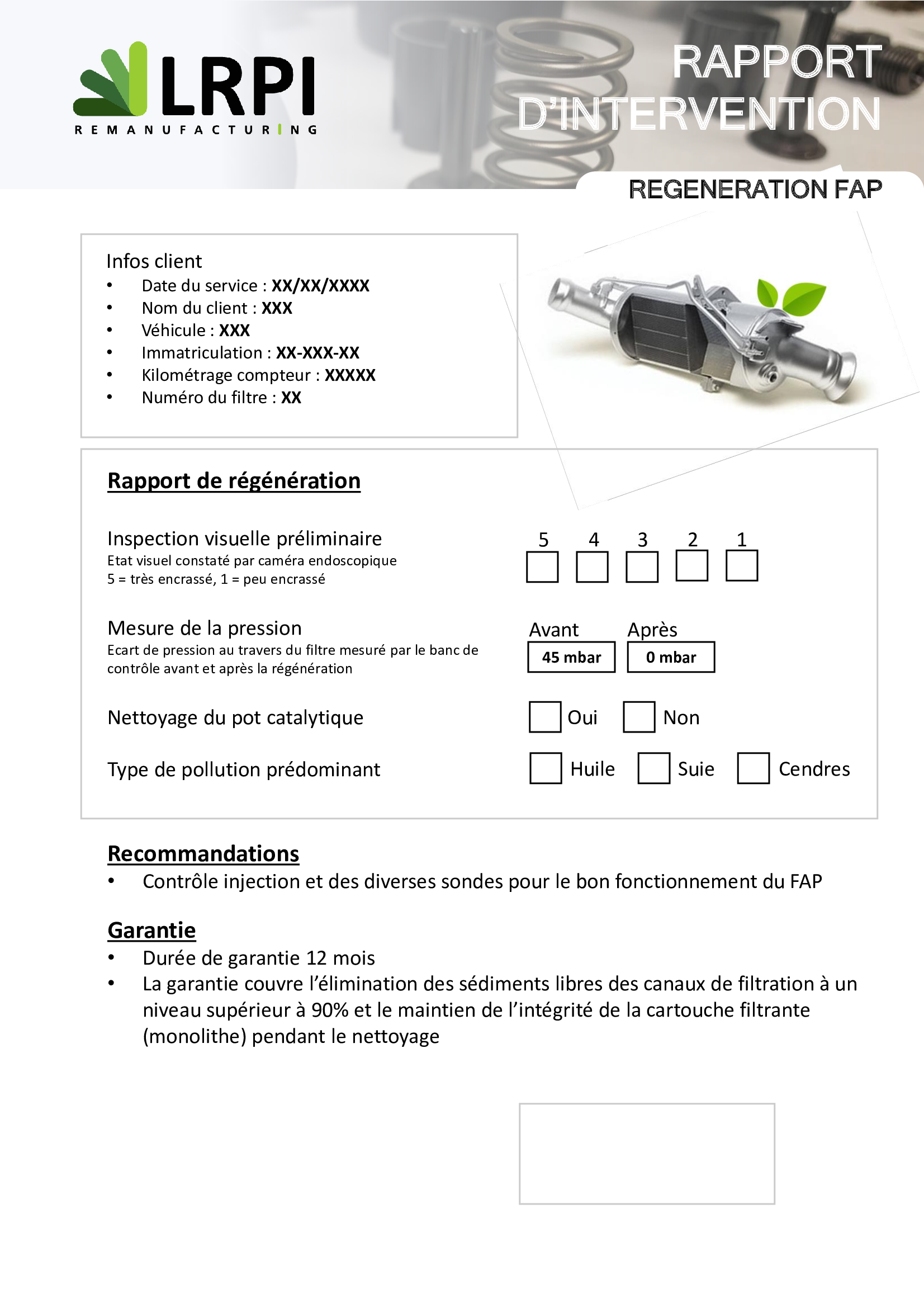

The Particulate Filter

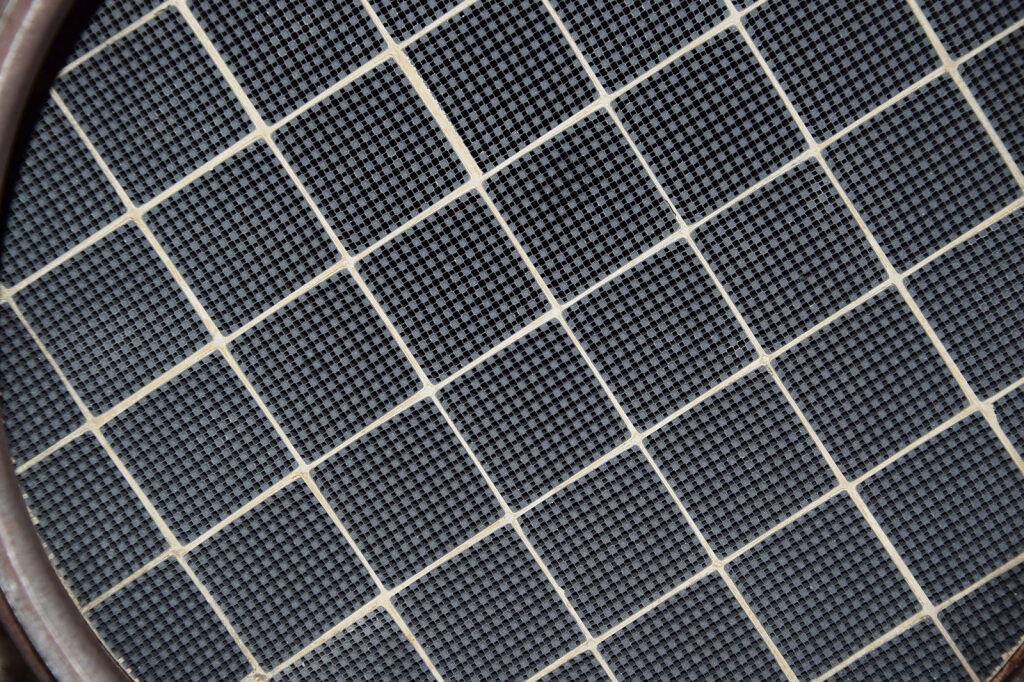

The main function of the DPF is to reduce hydrocarbon and carbon particulate emissions from diesel engines contained in exhaust gases.

It has been mandatory for all diesel vehicles since 2000. To prevent particles from clogging the filter, it is important to regenerate it.

Why buy new when you can regenerate the original DPF

Advantages of the rejuvenated particulate filter :

Preservation of the original part

Regenerating your original DPF avoids replacing it with a lower quality and less durable adaptable part

Reduction of repair costs

Allows reducing the repair cost by 50 to 80% compared to replacing the part with a new one

Equivalent lifespan to a new part

A rejuvenated DPF effectively filters fine particles for a duration equivalent to a new part

More performance, less pollution

A rejuvenated DPF contributes to reducing fine particulate emissions and significantly improves engine performance

Reduction of environmental impact

A rejuvenated DPF saves 100% of material consumption and reduces CO2 emissions by 70% compared to manufacturing a new DPF