Light vehicles

Light duty vehicles

Heavy trucks

Public works

Agricultural vehicles

Lifting equipment

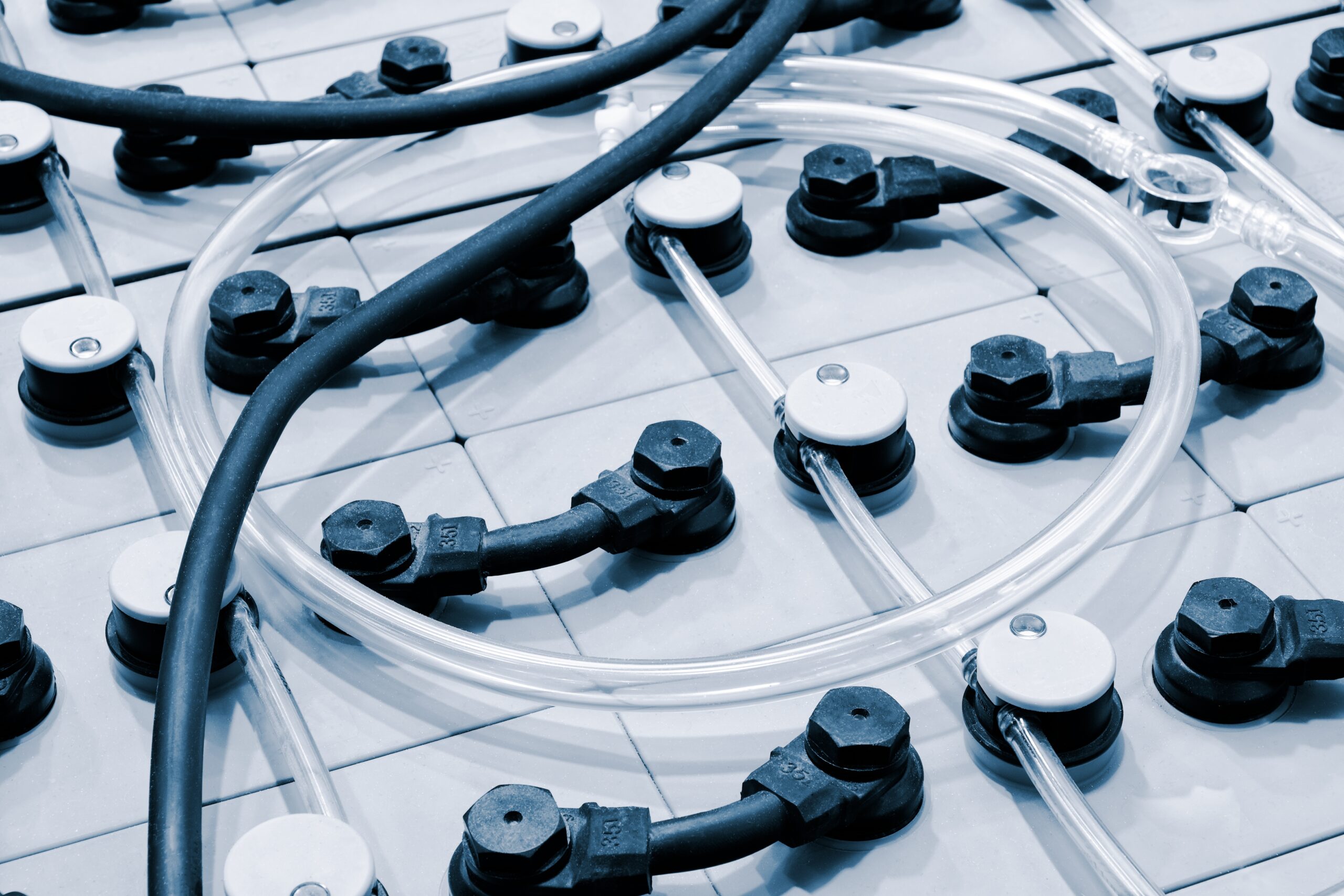

Battery Regeneration Process

Over cycles of charging and discharging, your battery’s capacity decreases and its performance becomes less efficient. It is the lead sulfate that solidifies and suffocates the battery.

Regeneration dissolves the lead sulfate crystals that have formed on the surface of the lead plates and gives the battery a second life with characteristics very close to new.

Starting

For heavy trucks, industrial vehicles, agricultural, public works, …

Traction

For pallet trucks, forklifts, industrial vehicles, carts, …

Stationary

For electricity storage centers (especially telecommunication centers)

Why buy new when you can regenerate the original battery

Advantages of the rejuvenated battery :

Economic

Battery regeneration, initially intended for recycling, can double their lifespan and save about 50% compared to buying equivalent new batteries

Environment

Battery regeneration allows for engagement in a circular economy model with 7 times fewer CO2 emissions than acquiring a new battery, saving rare raw materials, and reducing your industrial waste

Quality

Battery regeneration allows them to be brought back to their optimal performance and capacity, and you benefit from a one-year warranty