Our remanufactured products

LRPI has 30 years of expertise in automotive parts renovation

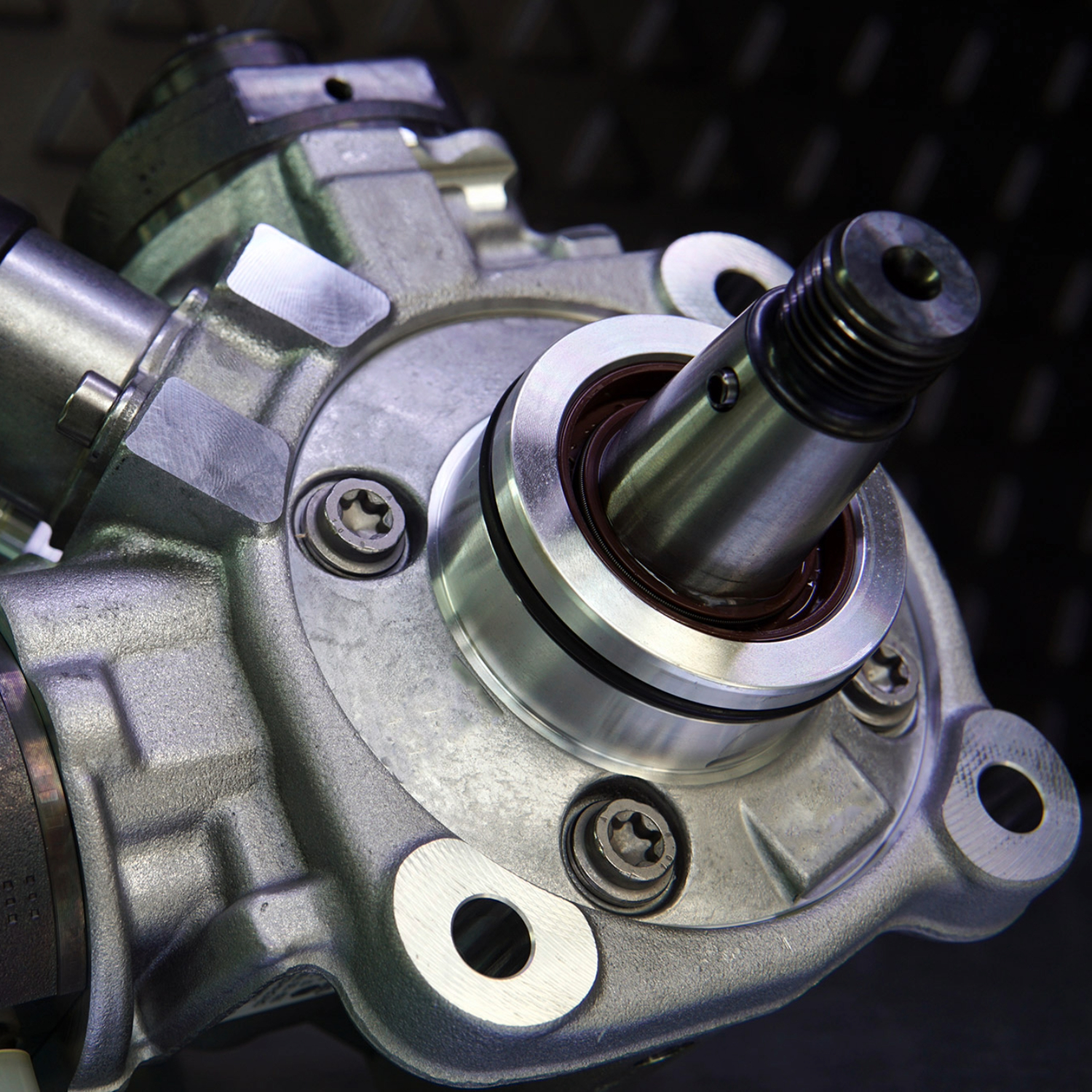

Injector

Particulate filter

Injection pump

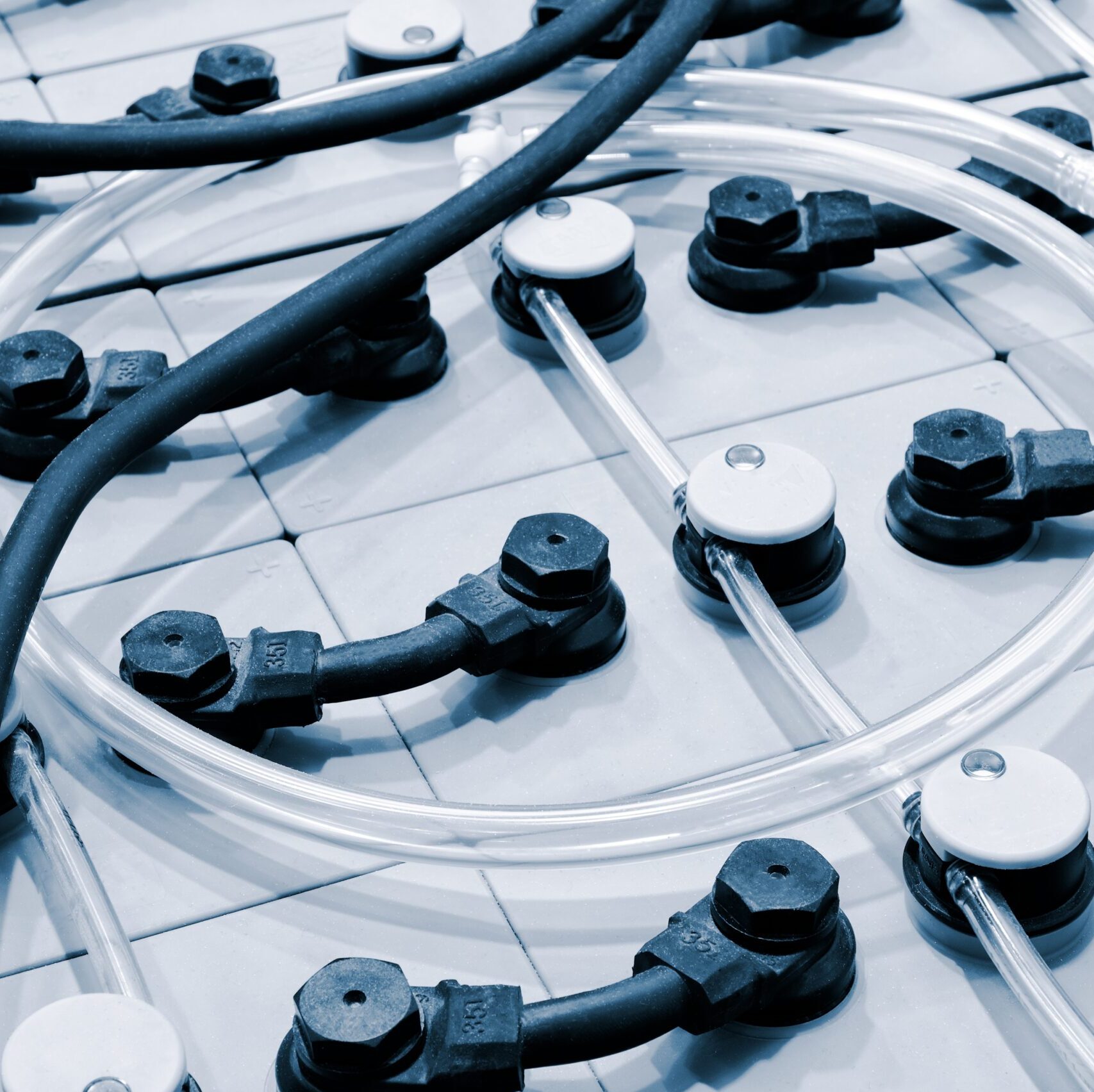

Battery

Our expertise

30 years of expertise in the renovation of pumps and injectors for all types of vehicles, and now all types of particulate filters

450 references available in standard exchange. A team of remanufacturing experts

A state-of-the-art production tool (ISO 7 clean room standard)

Making a new product from a used product, that is LRPI’s mission.

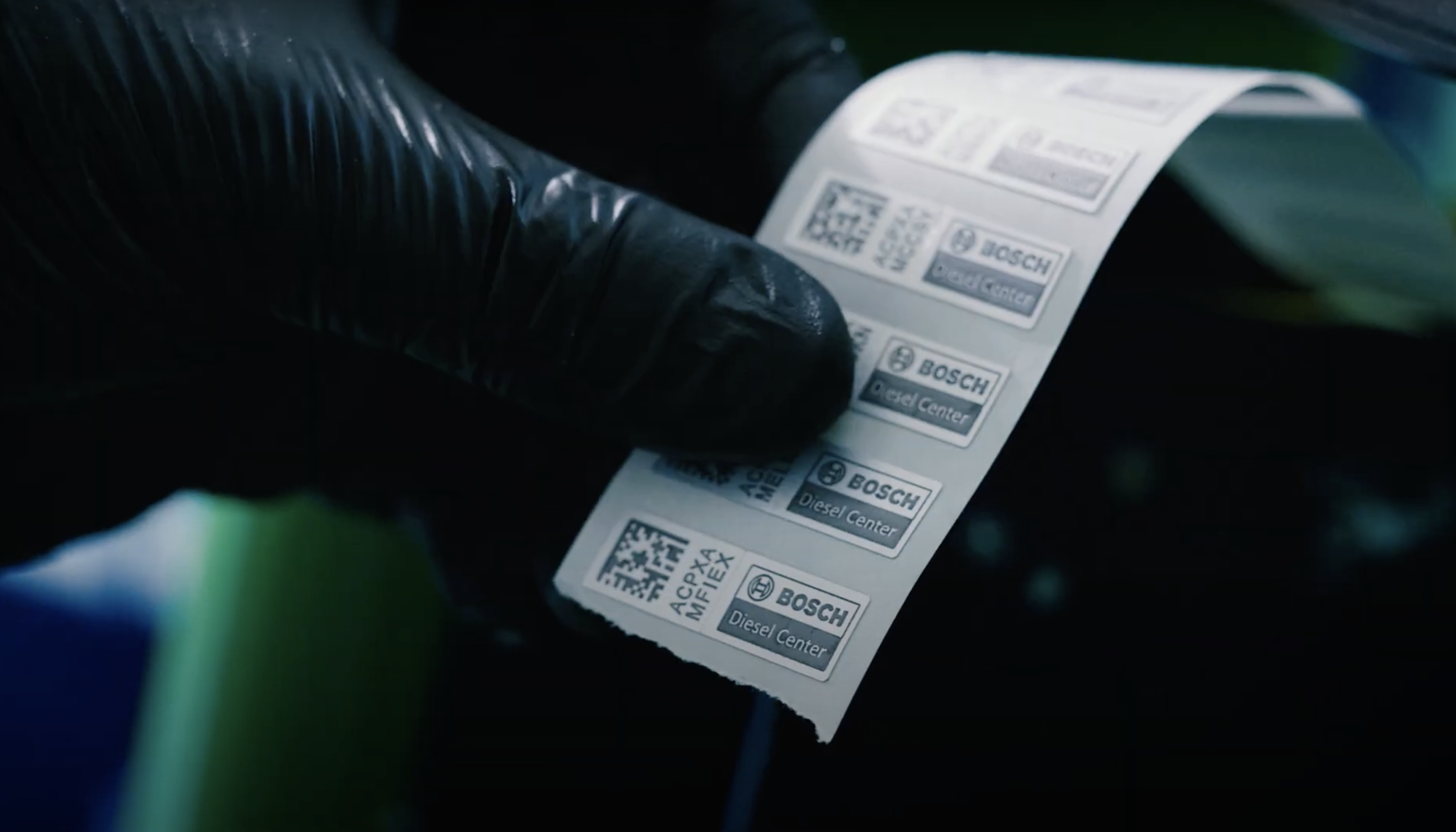

How to identify the real remanufactured product ?

Everything you need to know to make the best choice

1. Ask for certifications

Recognized remanufacturers can present high certification levels of their site and process (ISO 9001 for example)

2. Demand guarantees

Official remanufacturers can offer the same level of warranty as the new product. Generally, we are talking about 2 years or 60,000km.

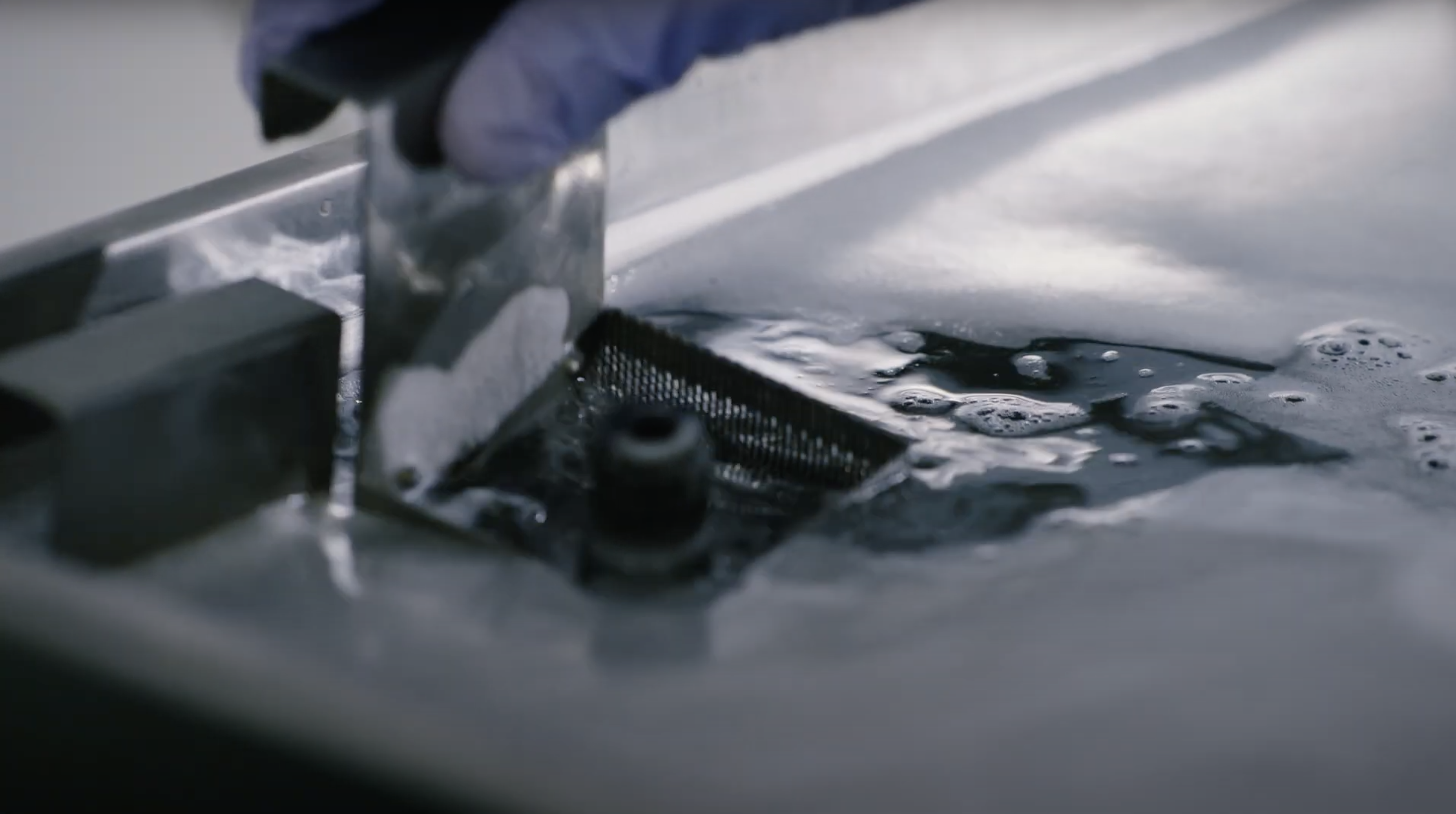

3. Check the industrial process

High-quality remanufacturing involves :

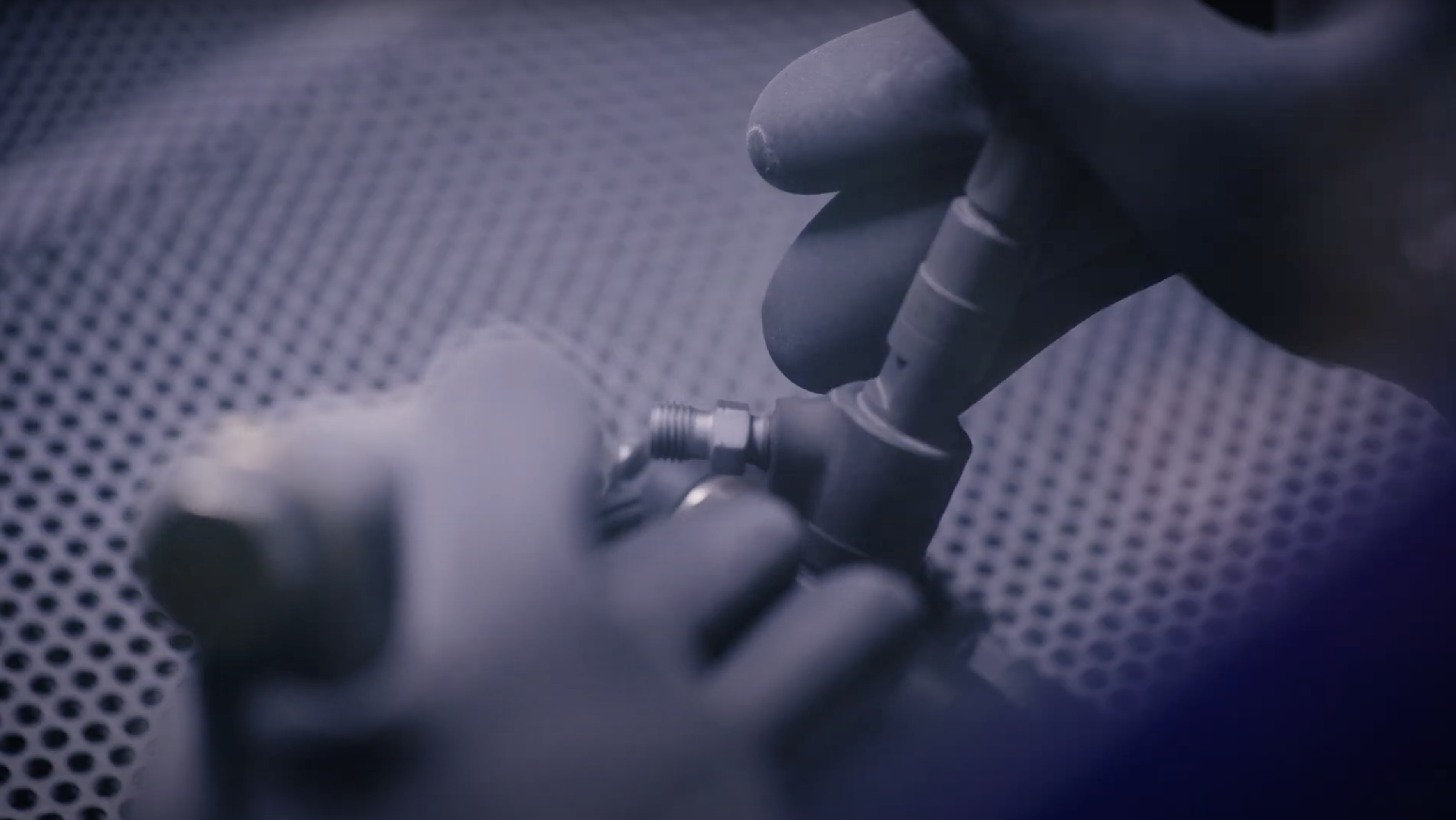

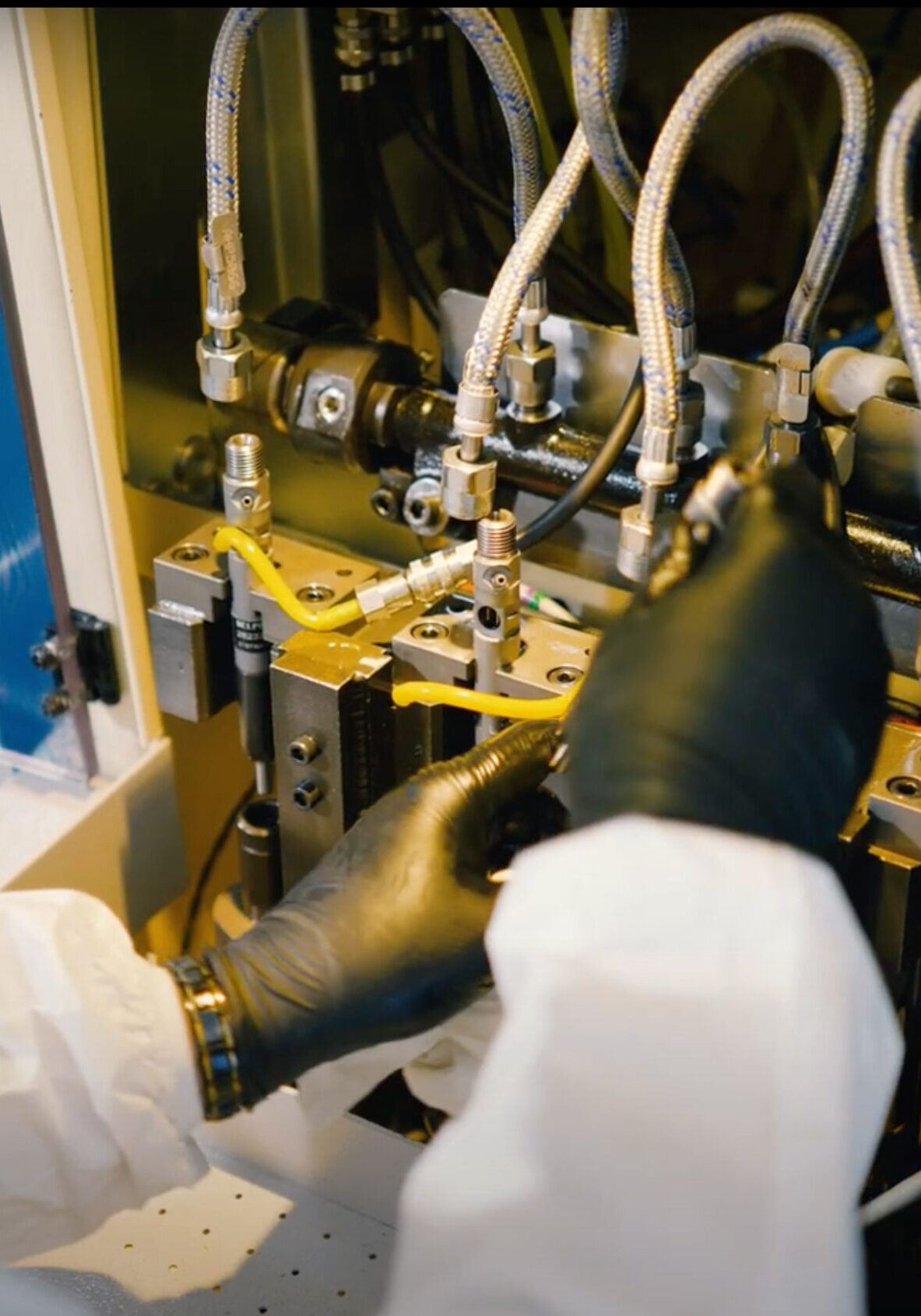

- Reassembly in a clean air clean room

- Replacement of ALL wear components (tip, clamping nuts, internal components…)

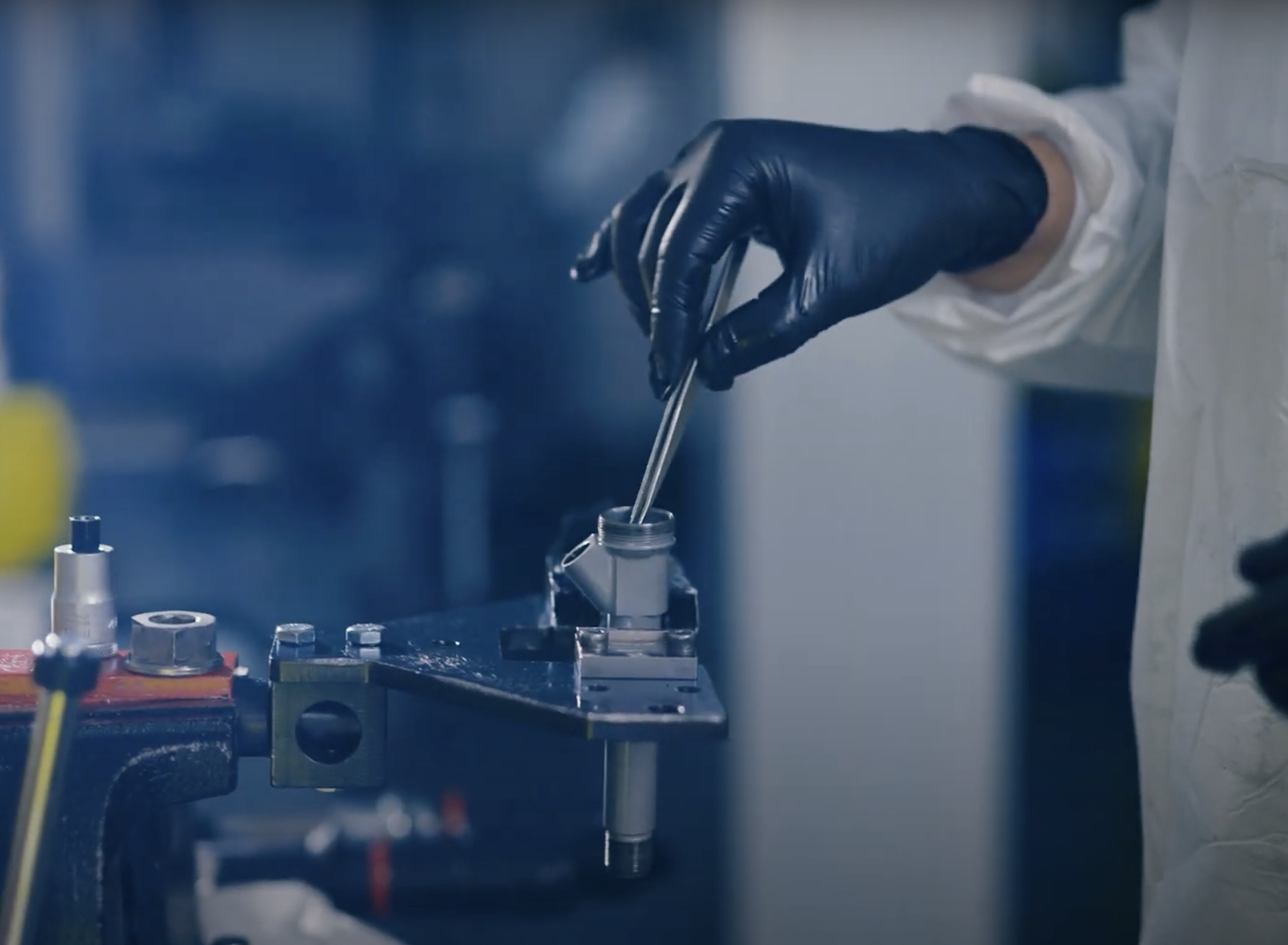

- Final validation of products on official benches certified by the original equipment manufacturers

Warning: without these conditions met, you risk buying a product that is simply checked or repaired, with much lower performance and lifespan

Steps of the reconditioning

Tate-of-the-art tools

ISO 7 certified clean room

- Clean room integrating all stages of testing and assembly

- Air treatment and overpressure

- Total elimination of particles > 0.5 μm

Equipment manufacturer approval

- Annual remanufacturing process and bench approval according to the equipment manufacturer’s specifications

- Validation of injectors and CR pumps on the bench according to the equipment manufacturer’s test protocol

- Global product traceability

- Equipment manufacturer warranty